SRM Faculty's Advanced Learning Journey: Exploring FPGA Technology and Industrial Innovation Unlocking the Future of Semiconductor Design

Faculty members from SRM Institute of Science and Technology recently embarked on a transformative industrial visit that showcased cutting-edge FPGA (Field-Programmable Gate Array) technology and its revolutionary applications in modern engineering. This immersive experience demonstrated how academic institutions are bridging the gap between theoretical knowledge and industrial practice through hands-on exploration of emerging technologies. The visit highlighted the critical role that FPGAs play in today’s industrial automation, artificial intelligence acceleration, and embedded systems development.[1][2][3][4][5][6]

University engineering students engaged in hands-on FPGA development in a laboratory setting.

The Strategic Importance of Industrial Visits for Academic Excellence SRM Institute of Science and Technology has consistently maintained its position as a leading engineering institution in India, currently ranked 12th overall among universities by NIRF 2024 and holding prestigious accreditations including NAAC A++ grade. The institute’s commitment to providing world-class education extends beyond traditional classroom learning through strategic industrial partnerships and experiential learning opportunities. These industrial visits serve as crucial bridges between academic theory and real-world application, enabling faculty members to stay current with rapidly evolving technological landscapes.[1][7][8][9]

The importance of such educational initiatives cannot be overstated in today’s fast-paced technological environment. As industries increasingly adopt sophisticated automation systems, artificial intelligence, and embedded computing solutions, academic institutions must ensure their curriculum remains relevant and practical. SRM’s proactive approach to faculty development through industrial exposure ensures that students receive education that is both theoretically sound and industrially applicable.[10][6][11][1]

Understanding FPGA Technology: The Foundation of Modern Digital Systems

Field-Programmable Gate Arrays represent a revolutionary approach to digital circuit design, offering unprecedented flexibility and performance in hardware implementation. Unlike traditional microprocessors that execute software instructions sequentially, FPGAs consist of configurable logic blocks that can be programmed to perform specific functions in parallel. This fundamental difference makes FPGAs particularly valuable for applications requiring real-time processing, low latency, and high throughput.[3][12][4][5][13][14]

The architecture of FPGAs comprises several key components that contribute to their versatility. Configurable Logic Blocks (CLBs) form the core processing elements, containing lookup tables, flip-flops, and multiplexers that can be configured to implement various digital functions. Programmable interconnects provide flexible routing between logic blocks, enabling complex circuit implementations. Additionally, modern FPGAs include specialized components such as Digital Signal Processing (DSP) blocks, embedded memory, and high-speed I/O interfaces.[12][4][5][15][16]

The programming of FPGAs utilizes Hardware Description Languages (HDLs) such as VHDL or Verilog, allowing engineers to describe digital circuits at various levels of abstraction. This programming paradigm differs significantly from software development, as engineers essentially design custom hardware architectures optimized for specific applications. The synthesis process then translates HDL code into actual hardware configurations, enabling the FPGA to function as a specialized digital circuit.[4][13][9][17][12]

Performance Comparison of Processing Technologies for Industrial Applications

FPGA Applications in Industrial Automation and Control Systems

The industrial automation sector has embraced FPGA technology for its ability to provide deterministic, real-time control with exceptional precision and reliability. Unlike general-purpose processors, FPGAs offer guaranteed timing characteristics essential for critical industrial processes. This deterministic behavior is particularly crucial in applications such as motor control, where precise timing can significantly impact system efficiency and safety.[6][18][11][8][19][20]

Motor control applications represent one of the most compelling use cases for FPGA technology in industrial settings. Traditional motor control systems often rely on microcontrollers or digital signal processors, but these solutions may struggle with the complex algorithms required for advanced control schemes. FPGAs excel in implementing Field-Oriented Control (FOC) algorithms, Pulse Width Modulation (PWM) generation, and sensor feedback processing simultaneously. The parallel processing capability of FPGAs enables multiple motor control loops to operate independently on a single chip, reducing system complexity and cost.[21][19][22][23][24][25]

Industrial communication protocols also benefit significantly from FPGA implementation. Modern factories require seamless integration between various automation components using diverse communication standards such as EtherCAT, PROFINET, and Industrial Ethernet. FPGAs can simultaneously support multiple communication protocols while maintaining real-time performance characteristics. This flexibility allows industrial systems to evolve and adapt to new communication standards without requiring complete hardware redesigns.[11][22][26][27][6]

The integration of artificial intelligence and machine learning capabilities into industrial systems represents another frontier where FPGAs demonstrate exceptional value. Edge computing applications in manufacturing require real-time AI inference for applications such as quality control, predictive maintenance, and autonomous decision-making. FPGAs provide the computational power needed for neural network implementation while maintaining the low latency and power efficiency required for industrial edge devices.[28][5][29][30][6]

FPGA Technology in Educational and Training Environments

The complexity of FPGA technology necessitates comprehensive educational approaches that combine theoretical understanding with practical hands-on experience. Educational institutions worldwide have recognized the importance of FPGA training in preparing students for careers in modern engineering disciplines. The curriculum typically progresses from fundamental digital logic concepts through advanced topics such as embedded system design and artificial intelligence implementation.[31][32][33][34][35]

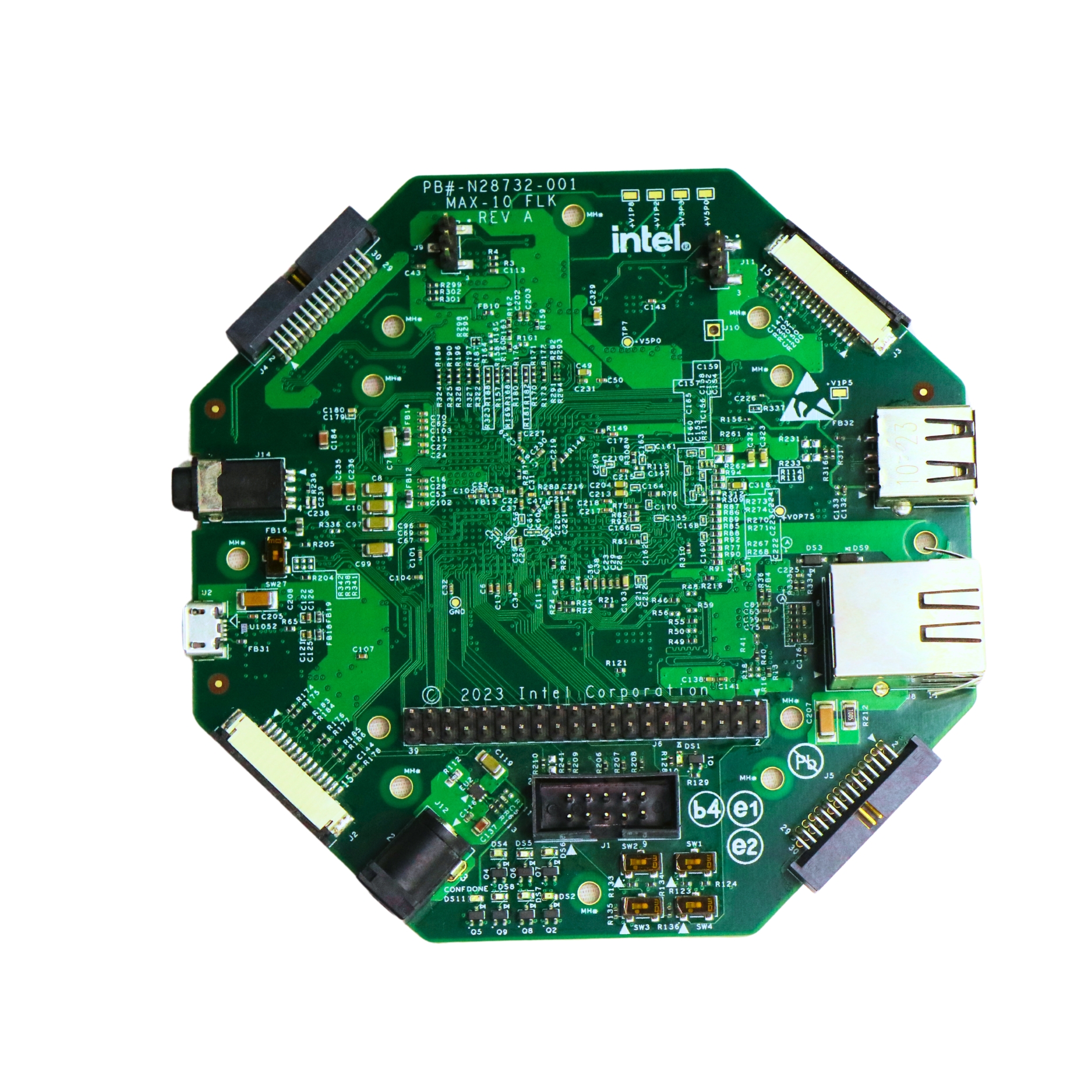

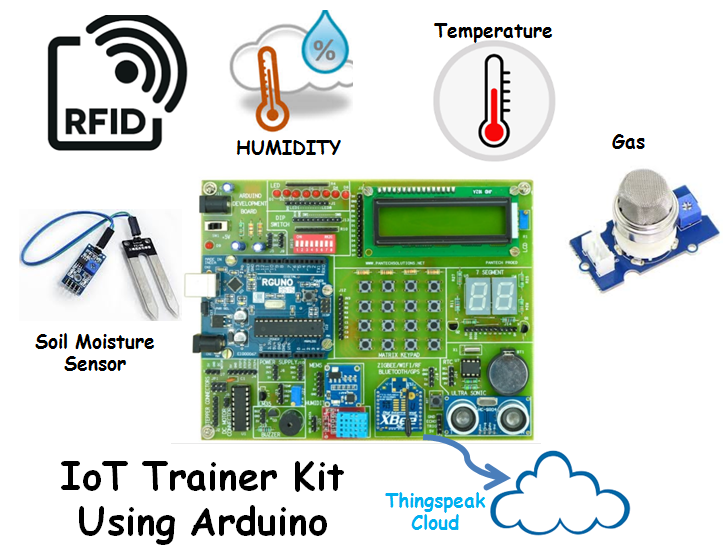

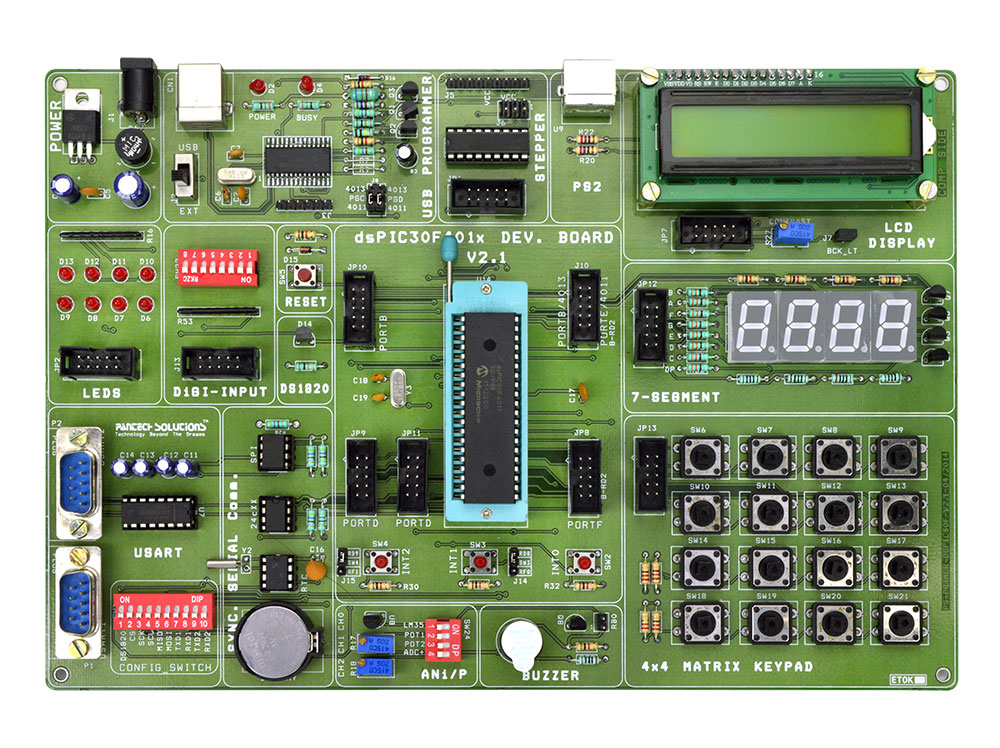

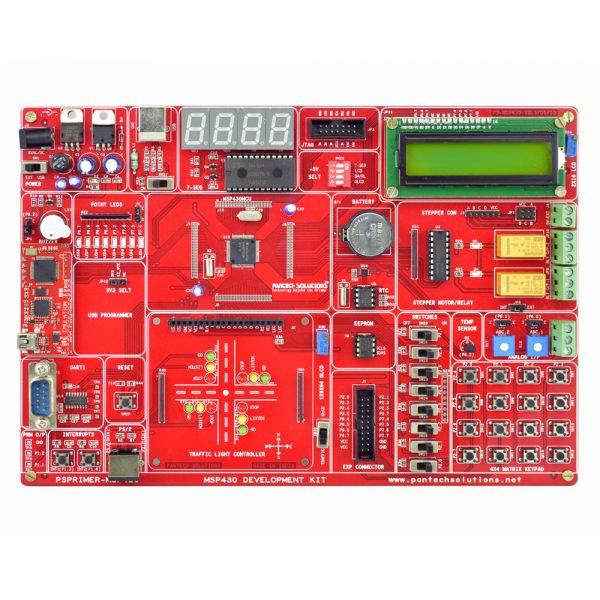

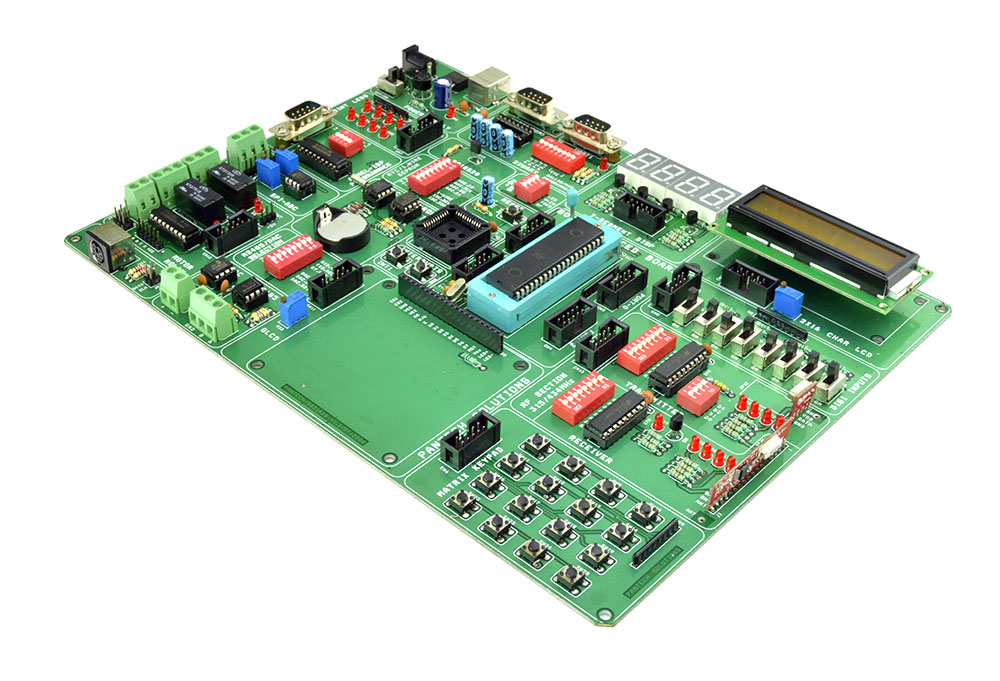

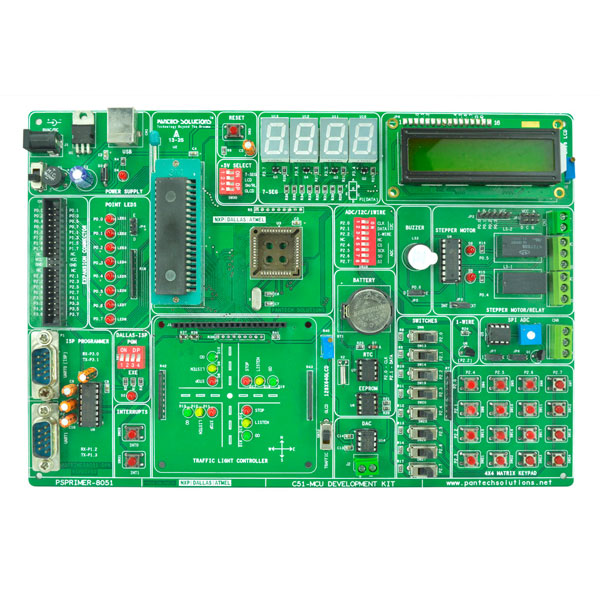

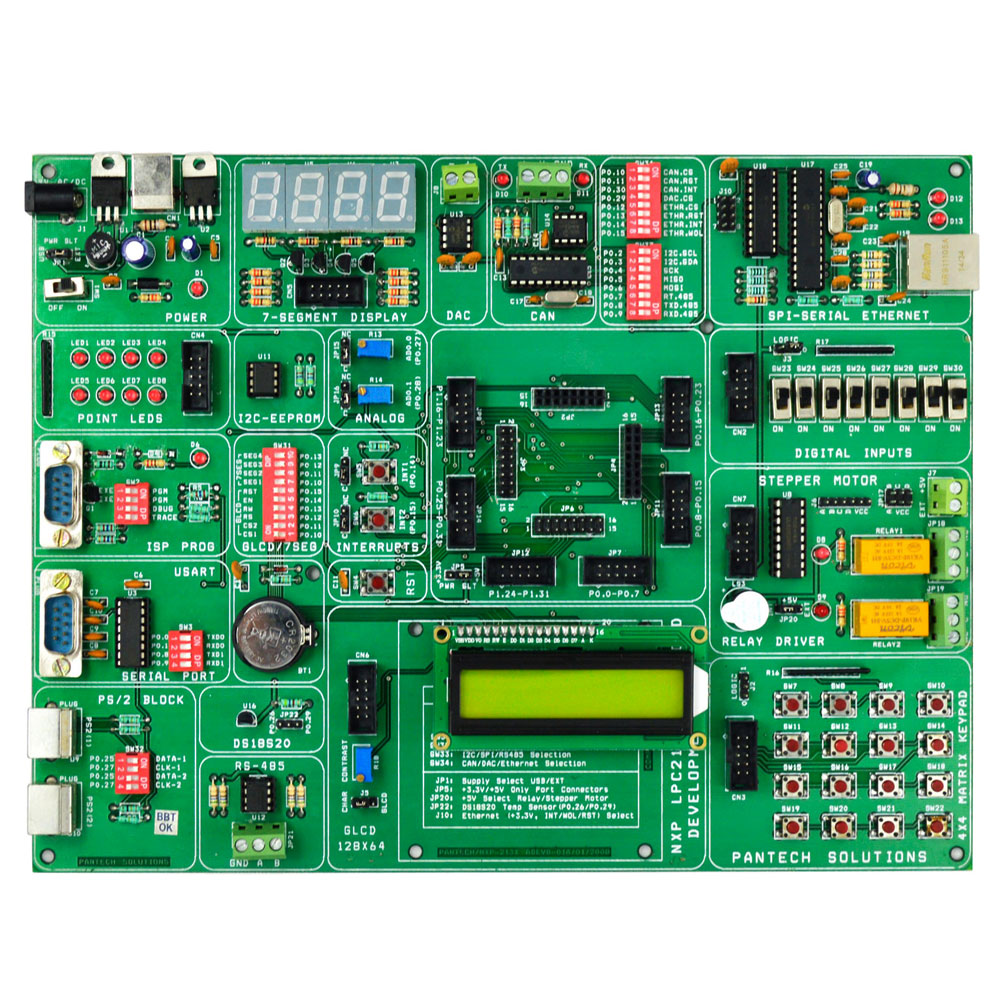

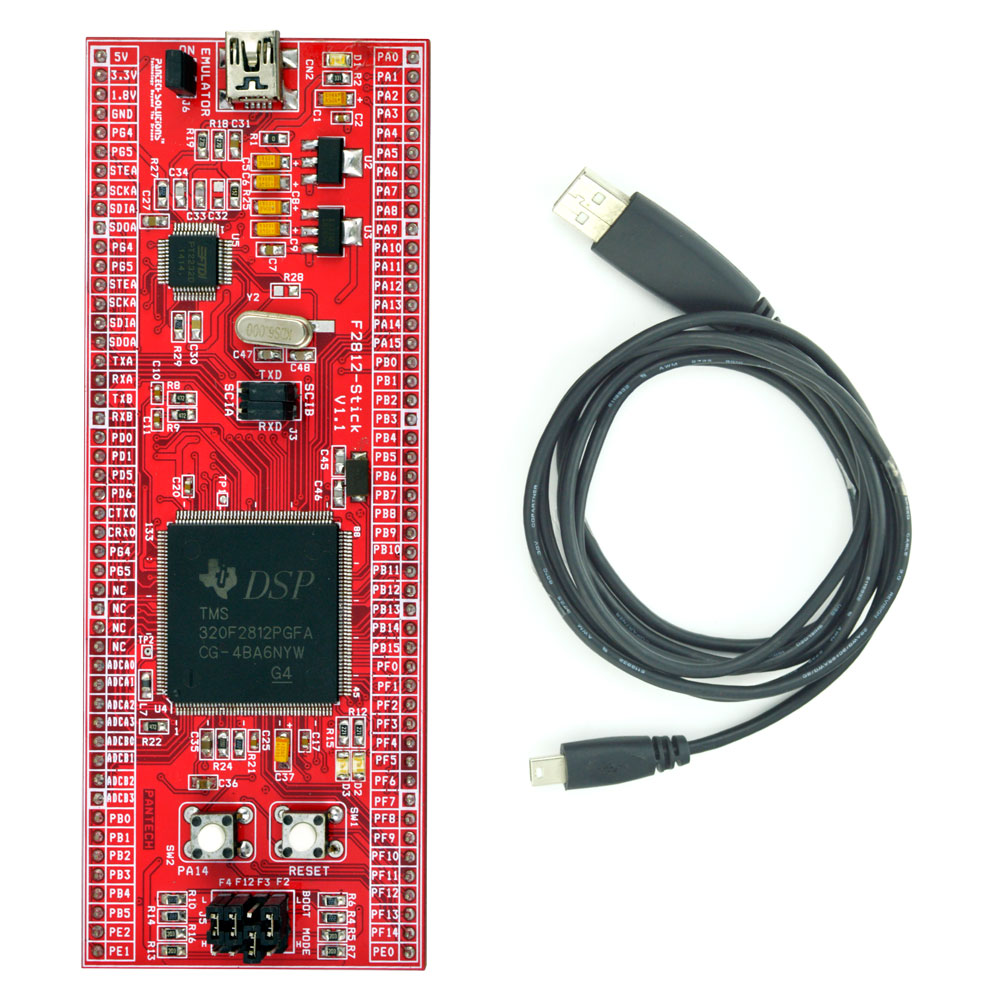

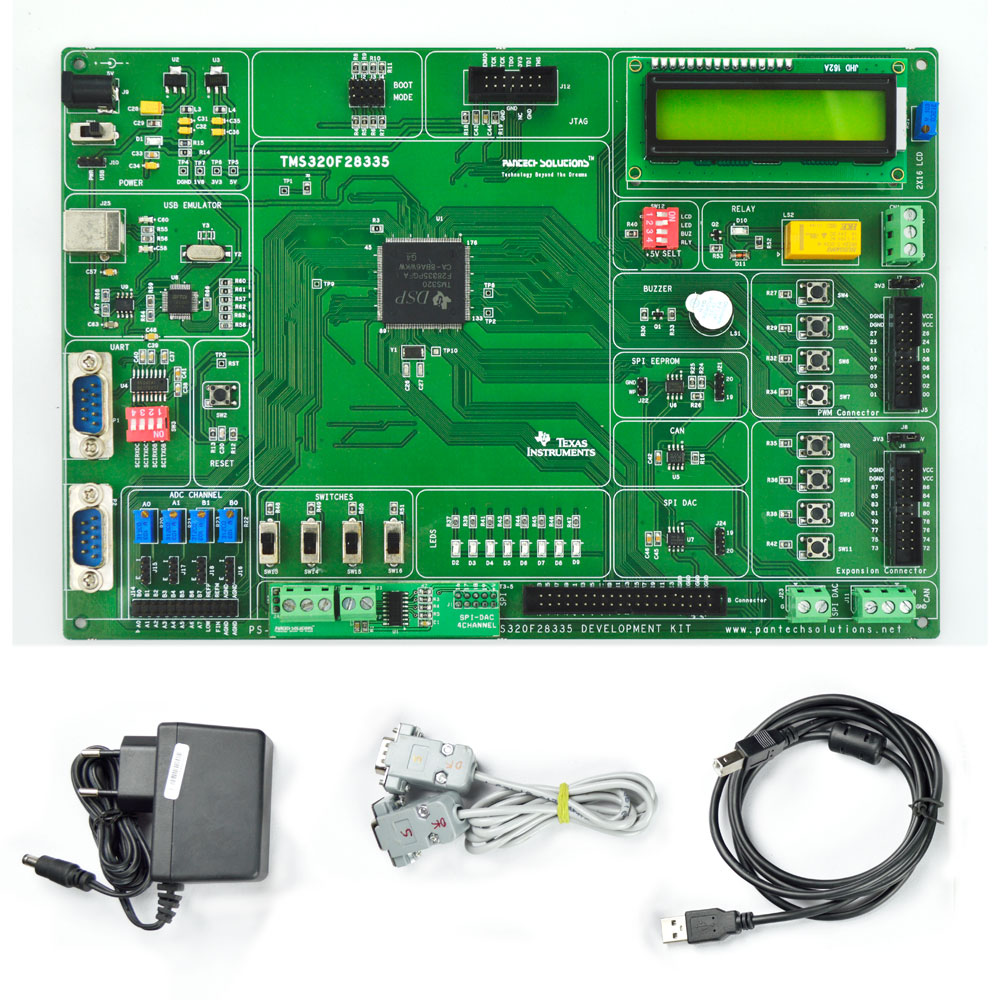

Laboratory-based learning forms the cornerstone of effective FPGA education, providing students with direct experience in hardware description language programming, synthesis, and debugging. Modern educational FPGA platforms, such as the Altera MAX10 development boards, offer comprehensive learning environments with integrated peripherals, sensors, and communication interfaces. These platforms enable students to implement complete systems ranging from simple digital circuits to complex embedded applications.[36][32][37][33][38][39]

The progression of FPGA education typically follows a structured pathway beginning with basic logic design and VHDL programming. Students learn to implement fundamental digital circuits such as counters, state machines, and arithmetic units before advancing to more complex applications. Intermediate topics include sensor interfacing, motor control, and communication protocol implementation. Advanced coursework covers image processing, artificial intelligence acceleration, and system-on-chip design.[32][33][34][35][40][41][31]

Engineering students engaged in hands-on FPGA development laboratory work in a university Electronics and Communications department.

Hands-On Demonstrations: Bridging Theory and Practice

The industrial visit showcased several compelling demonstrations that illustrated the practical applications of FPGA technology in real-world scenarios. These demonstrations provided faculty members with tangible examples of how theoretical concepts translate into functional industrial solutions. The hands-on approach enabled deeper understanding of FPGA capabilities and limitations while highlighting the technology’s potential for addressing complex engineering challenges.[42][8][9]

MNIST AI Inference Implementation represented one of the most impressive demonstrations, showcasing an FPGA-based handwritten digit recognition system. This application demonstrated the FPGA’s ability to accelerate artificial intelligence workloads with significantly reduced latency compared to traditional CPU-based implementations. The system achieved recognition performance up to 488 times faster than conventional software-based approaches, illustrating the substantial performance advantages that FPGAs can provide for AI applications.[28][5][43][42]

Motor Control via PWM demonstrations highlighted the precision and efficiency achievable through FPGA-based control systems. The implementation showcased precise speed control of DC motors using PWM signals generated directly from the FPGA hardware. The demonstrated system achieved up to 20x lower power consumption compared to traditional microcontroller-based solutions while providing superior control accuracy and response time. This demonstration particularly resonated with faculty members involved in mechatronics and automation engineering curricula.[21][19][23][24][25][42]

The Interactive Ping Pong Game demonstration provided an engaging example of real-time graphics processing and user interface implementation using FPGAs. Built using Verilog and rendered through VGA output, this demonstration showcased concepts such as game logic implementation, input handling, and real-time visual processing. While seemingly simple, this application illustrated the FPGA’s capability to handle multiple concurrent tasks including graphics rendering, input processing, and game state management simultaneously.[14][15][42]

VGA Monitor Interfacing demonstrations showcased the FPGA’s capability for real-time video signal processing and custom display generation. This application highlighted the potential for implementing sophisticated visual inspection systems and custom user interfaces in industrial applications. The demonstration illustrated how FPGAs can generate precise timing signals required for video standards while simultaneously processing image data for analysis or enhancement.[30][40][42][14]

Industry Collaboration and Knowledge Transfer

The partnership between academic institutions and technology companies plays a crucial role in advancing engineering education and research capabilities. Industrial visits facilitate direct knowledge transfer between practitioners and educators, ensuring that academic programs remain aligned with industry needs and technological trends. This collaboration benefits both parties: industries gain access to research capabilities and fresh perspectives, while academic institutions ensure their curricula remain relevant and practical.[1][7][11][8][44][27]

Technology companies specializing in FPGA development have established comprehensive educational programs and partnerships with universities worldwide. These programs provide access to cutting-edge development tools, reference designs, and technical support that would otherwise be unavailable to academic institutions. The collaboration extends beyond simple tool provision to include curriculum development, faculty training, and student internship opportunities.[31][32][45][38][34][35]

The democratization of FPGA technology through educational partnerships has significantly lowered the barriers to entry for students and researchers. Modern development environments provide high-level programming interfaces that allow students to focus on application development rather than low-level hardware details. This accessibility enables broader adoption of FPGA technology across diverse engineering disciplines.[33][40][39][8][9][31]

Industry-standard development practices introduced through these partnerships ensure that students graduate with relevant skills and experience. Exposure to professional development methodologies, verification techniques, and project management approaches prepares students for immediate contribution to industry projects. This alignment between academic preparation and industry expectations enhances graduate employability and career advancement prospects.[10][32][34][41][1][33]

Future Prospects and Emerging Applications

The future of FPGA technology appears exceptionally promising, with emerging applications spanning diverse domains from 5G communications and autonomous vehicles to edge AI and quantum computing. The increasing complexity of modern systems and the growing demand for real-time, low-latency processing continue to drive FPGA adoption across industries. Educational institutions must prepare students for this evolving landscape by providing comprehensive FPGA education and training.[5][46][6][11][8][44]

Artificial intelligence and machine learning acceleration represents one of the most significant growth areas for FPGA technology. As AI models become increasingly complex and deployment moves toward edge devices, FPGAs provide an ideal platform for inference acceleration. The flexibility of FPGAs enables optimization for specific neural network architectures while maintaining the ability to adapt to evolving AI algorithms.[28][29][43][46][5]

5G and beyond wireless communications present substantial opportunities for FPGA applications in both infrastructure and device implementations. The demanding requirements for low latency, high throughput, and flexible protocol support align perfectly with FPGA capabilities. Educational programs must incorporate these emerging applications to ensure students are prepared for the next generation of communication systems.[33][41][6][11][5]

Edge computing and Internet of Things (IoT) applications continue to expand the market for FPGA technology. The requirement for intelligent processing at the network edge, combined with power and cost constraints, makes FPGAs an attractive solution for many IoT applications. Students must understand how to leverage FPGA technology for edge computing applications to remain competitive in the evolving job market.[30][11][8][9][44][26]

Conclusion

The industrial visit undertaken by SRM Institute of Science and Technology faculty members exemplifies the institution’s commitment to providing cutting-edge education and staying current with technological advances. Through direct exposure to FPGA technology and its industrial applications, faculty members gained valuable insights that will enhance their teaching capabilities and research directions. This experience demonstrates the critical importance of industry-academia collaboration in maintaining educational relevance and preparing students for successful engineering careers.[1][2][11][8][9][27]

The demonstrated applications of FPGA technology, from AI acceleration to motor control, illustrate the vast potential for these devices in modern engineering applications. As industries continue to embrace automation, artificial intelligence, and edge computing, the demand for engineers skilled in FPGA technology will continue to grow. Educational institutions must ensure their programs provide comprehensive FPGA education to meet this growing demand.[42][28][5][31][33][6]

The success of such industrial visits reinforces the value of experiential learning in engineering education. By providing faculty members with direct exposure to cutting-edge technology and applications, these programs ensure that classroom instruction remains practical, relevant, and inspiring. The knowledge and enthusiasm gained through such experiences ultimately benefit students and contribute to the advancement of engineering education and practice.[32][41][8][9][44][1]

-

- https://www.shiksha.com/university/srm-institute-of-science-and-technology-kattankulathur-chennai-24749

- https://en.wikipedia.org/wiki/SRM_Institute_of_Science_and_Technology

- https://www.logic-fruit.com/blog/fpga/fpga-design-architecture-and-applications/

- https://www.ibm.com/think/topics/field-programmable-gate-arrays

- https://www.intel.com/content/www/us/en/learn/fpga-for-ai.html

- https://www.intel.com/content/www/us/en/fpga-solutions/industrial/overview.html

- https://www.srmup.in

- https://www.acldigital.com/blogs/role-of-fpgas-for-embedded-system

- https://lembergsolutions.com/blog/fpga-programming-when-use-in-your-embedded-system

- https://srmrmp.edu.in

- https://www.bostk.com/blog/fpga-applications-in-industry-and-communication-58

- https://www.tutorialspoint.com/digital-electronics/field-programmable-gate-arrays.htm

- https://en.wikipedia.org/wiki/Field-programmable_gate_array

- https://www.ni.com/en/shop/electronic-test-instrumentation/add-ons-for-electronic-test-and-instrumentation/what-is-labview-fpga-module/fpga-fundamentals.html

- https://www.arm.com/glossary/fpga

- https://www.geeksforgeeks.org/digital-logic/fpga-full-form/

- https://www.embedded.com/embedded-design-with-fpgas-development-process/

- https://www.slideshare.net/udaywankar/fpga-based-motor-controller-43062779

- https://www.caeaccess.org/archives/volume1/number4/321-1523/

- https://conclusive.tech/glossary/the-role-of-fpga-in-realizing-efficient-embedded-solutions/

- https://imperix.com/doc/implementation/fpga-pwm-modulator

- https://www.xilinx.com/publications/prod_mktg/Industrial-Automation-Solutions-Product-Brief.pdf

- https://ijcrt.org/papers/IJCRTX020005.pdf

- https://www.microchip.com/en-us/solutions/technologies/motor-control-and-drive/motor-control-products/fpga

- https://www.hackster.io/adam-taylor/fpga-based-motor-control-cd47e7

- https://www.latticesemi.com/en/Blog/2022/12/20/23/00/2022-How-FPGAs-Can-Make-Industry-4-Work

- https://www.altera.com/fpga-solutions/industrial

- https://promwad.com/services/embedded/fpga-design/ai

- https://www.bitsathy.ac.in/ai-on-fpga/

- https://www.microchip.com/en-us/solutions/industrial/fpga

- https://www.pantechsolutions.net/fpga-master-class

- https://pantech.ai/product/internship-on-fpga

- https://www.coursera.org/learn/fpga-architecture-based-system-for-industrial-application-using-vivado

- https://pantech.ai/product-tag/fpga

- https://learn.pantechsolutions.net/p/fpga-master-class

- https://pantechelearning.com/2025/05/07/max10-flk-dev-board/

- https://www.raypcb.com/intel-max-10-fpga-boards/

- https://www.intel.com/content/www/us/en/products/details/fpga/development-kits/max/10m50.html

- https://numato.com/product/telesto-max10-fpga-module/

- https://www.intel.com/content/www/us/en/products/docs/programmable/industrial-vision-ai-video.html

- https://digitalskills.iitmpravartak.org.in/course_details.php?courseID=228

- https://pantechelearning.com/2025/05/26/vit-staffs-industrial-visit-advancing-knowledge-in-fpga-development-e-mobility-autonomous-systems/

- https://fidus.com/blog/the-role-of-fpgas-in-ai-acceleration/

- https://embevity.com/what-is-an-fpga-and-do-you-need-it-in-your-embedded-system/

- https://learn.pantechsolutions.net

- https://www.amd.com/en/blogs/2025/from-invention-to-ai-acceleration–celebrating-40-years-of-fpga-.html

- All Projects

- Product