Battery management system(BMS)

Internship 2025

Learn battery simulation in MATLAB/Simscape, including thermal effects, aging, balancing, and SOC/health estimation. Design charging, discharging, temperature control, and BMS testing with communication protocols. Deploy BMS algorithms on hardware like NXPS32K.

1/ 2 Months

Online

8+ Live Projects

Dual Certification

Ultimate Step towards your Career Goals: Expert in BMS Technologies

Simulate and design battery systems in MATLAB/Simscape, including SOC/health estimation, charging, discharging, and BMS testing. Deploy algorithms on hardware like NXPS32K.

Internship Benifits

Mentorship

Receive guidance and insights from industry experts.

Hands-on Experience

Gain practical skills in a real-world cutting-edge projects.

Networking

Connect with professionals and peers in your field.

Skill Development

Enhance your technical and soft skills.

Career Advancement

Boost your resume with valuable experience.

Certificate

Get a certification to showcase your achievements.

BMS Internship Overview

Creating Basic Battery Module Simulation in MATLAB and Simscape

- Introduction to basic battery module simulation, covering cell behavior in MATLAB and Simscape.

Constructing Elementary Battery Pack Simulation in MATLAB and Simscape

- Building a basic battery pack model to understand cell configurations and interconnections.

Designing Battery Module Model Considering Thermal Influences

- Adding thermal effects to the battery module, simulating heat generation, and dissipation.

Developing Battery Pack Model Incorporating Cell Aging

- Integrating cell aging factors to simulate degradation over time and usage cycles.

Constructing Battery Pack Model with Integrated Cell Balancing Circuitry

- Simulating cell balancing techniques for uniform cell performance in a battery pack.

Creating Battery Pack Model for Grid-Connected Energy Systems

- Designing a battery model compatible with grid storage applications, focusing on energy exchange.

Designing Simulation Model for Hybrid Cell Battery Pack

- Modeling a hybrid battery pack with multiple cell types for varied performance requirements.

Develop a Battery Monitoring System using Simulink/Simscape

- Developing a monitoring system to track voltage, temperature, and other essential parameters.

Battery Charging and Discharging Circuit in Simulink/Simscape

- Implementing a simple charging and discharging circuit for battery pack performance analysis.

Design a Battery Pack with Passive Cell Balancing

- Simulating passive balancing methods for energy distribution within cells of a battery pack.

Battery State of Charge (SOC) Estimation Using Coulomb Counting in Simulink/Simscape

- Estimating SOC by tracking charge and discharge cycles through Coulomb counting.

Battery State of Charge Estimation Using Kalman Filter in Simulink/Simscape

- Employing Kalman filtering to predict SOC more accurately under dynamic conditions.

Battery State of Charge Estimation Using EKF/Unscented Kalman Filter in Simulink/Simscape

- Using advanced filtering methods for SOC estimation in highly non-linear battery models.

Battery State of Health (SOH) Estimation in Simulink/Simscape

- Implementing SOH tracking for real-time assessment of battery life and performance.

Designing Thermal Analysis for New and Aged Battery Packs

- Analyzing thermal behavior for both new and degraded batteries to study performance changes.

Developing Algorithms to Control Battery Temperature by Activating Heaters or Coolants

- Designing algorithms to regulate battery temperature using cooling and heating systems.

Designing Battery Controllers in MATLAB/Simulink

- Creating a control system for battery charging, discharging, and energy management.

Designing a Lithium Battery Cell 2RC Branch Equivalent Circuit in MATLAB/Simulink

- Modeling lithium battery cell behavior using a 2RC branch circuit for enhanced accuracy.

Battery Charging and Discharging Management in MATLAB/Simulink

- Implementing a controller to manage charging and discharging cycles, ensuring efficiency.

Communication Protocols – CAN Bus, LIN Bus, UART, etc.

- Introduction to communication protocols for BMS, focusing on integration with vehicle components.

Introduction to Testing BMS Software

- Overview of testing techniques to validate BMS performance and reliability.

Data Exchange Between BMS and Other Vehicle Components

- Exploring data transfer methods for effective communication between BMS and automotive systems.

Generating Code for BMS Using MATLAB/Simulink

- Code generation for BMS deployment, covering automated code creation from simulation models.

Closed-Loop Testing of BMS Using MATLAB/Simulink

- Running closed-loop tests to validate BMS response under simulated operational conditions.

Managing BMS Requirements in MATLAB/Simulink

- Using Simulink for managing system requirements, ensuring all design needs are met.

Deploying BMS Algorithms on NXP S32K from MATLAB/Simulink

- Deploying BMS control algorithms on NXP S32K MCU for real-world implementation.

Looking for in-depth Syllabus Information? Explore your endless possibilities in BMS with our Brochure!

share this detailed brochure with your friends! Spread the word and help them discover the amazing opportunities awaiting them.

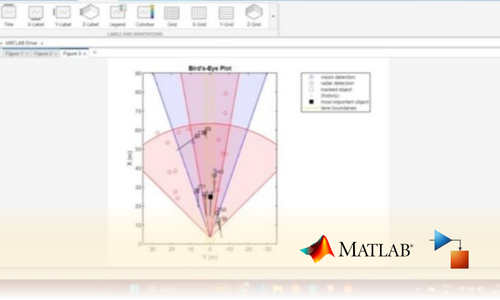

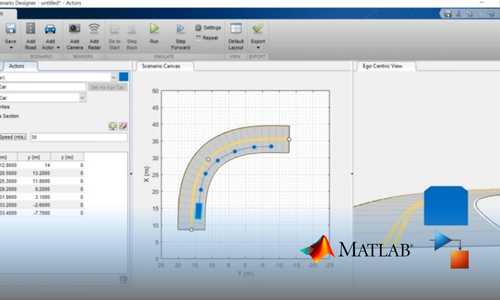

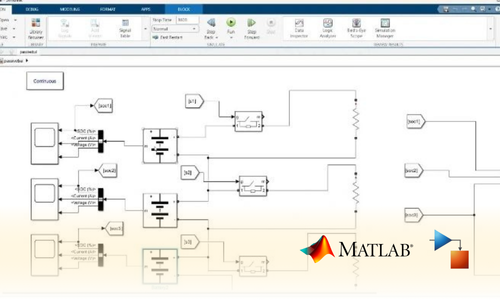

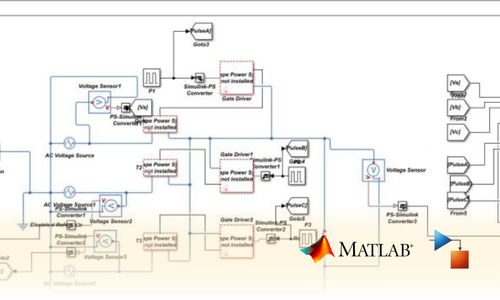

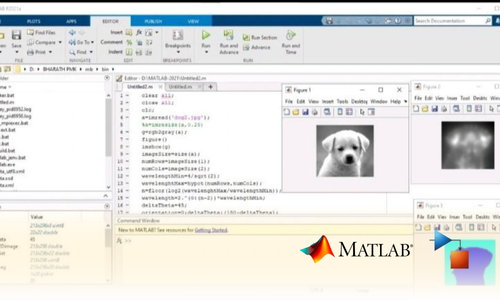

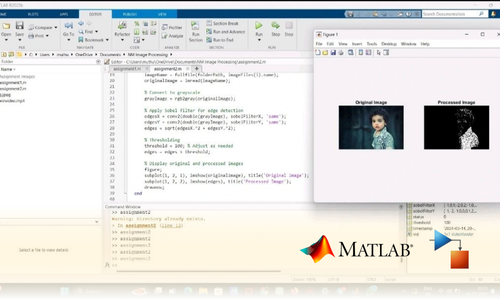

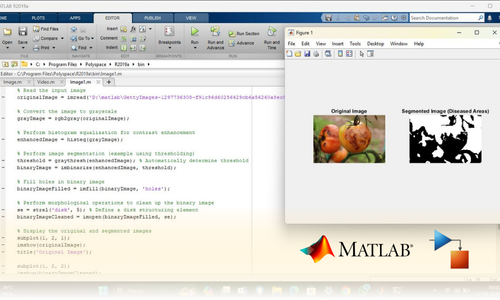

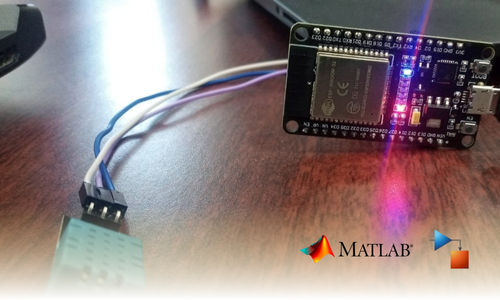

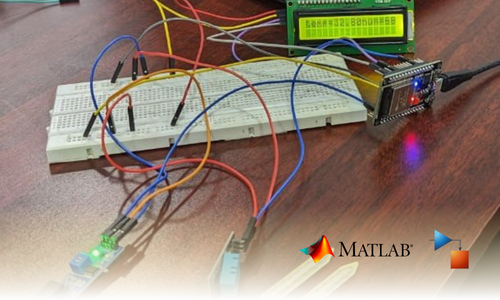

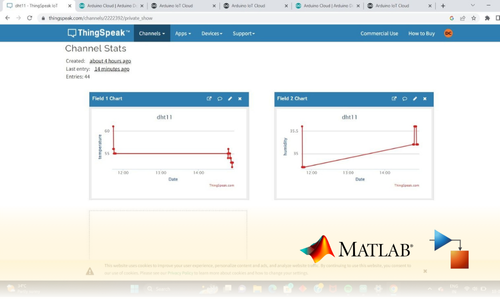

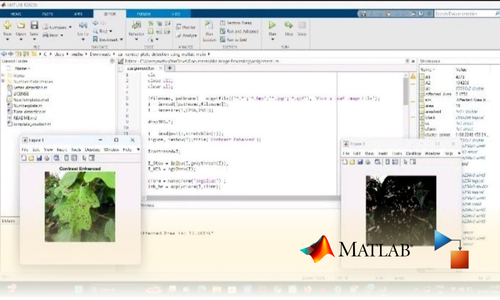

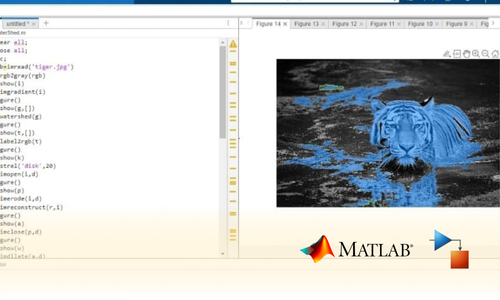

Project Submission: Example Output Screenshots from Our Clients

Take a look at these sample outputs crafted by our clients. These screenshots showcase the impressive results achieved through our courses and projects. Be inspired by their work and visualize what you can create!

Dual Certification: Internship Completion & Participation

Earn prestigious Dual Certification upon successful completion of our internship program. This recognition validates both your participation and the skills you have honed during the internship

How does this Internship Program Work?

Step 1 Enroll in the Program

- Get a Mentor Assigned

- Presentations & Practice Codes

- Learn at your Flexible Time

- Apprehend the concepts

Step 2 Project Development

- Implement Skills Learn

- Develop Projects with assistance

- Get Codes for Reference

- Visualise the Concepts

Step 3 Get Certified

- Certificate of Internship

- Project Completion Certificate

- Share on social media

- Get Job Notifications

Choose Your Plan fit your needs

Master the Latest Industrial Skills. Select a technology domain & kick off your Internship immediately.

1 Month

₹1999/-

₹999/-

- Internship Acceptance Letter

- 90 Days from the date of payment

- 4 LIVE intractive Mastermind Sessions

- 4+ Capstone Projects & Codes

- Full Roadmap

- Internship Report

- 1 Month Internship Certificate

2 Month

₹3299/-

₹1899/-

- Internship Acceptance Letter

- 180 Days from the date of payment

- 4 LIVE interactive Mastermind Sessions

- 12+ Capstone Projects & Codes

- Full Roadmap

- Internship Report

- Participation Certificate

- 2 Month Internship Certificate

Our Alumni Employers

Curious where our graduates make their mark? Our students go on to excel in leading tech companies, innovative startups, and prestigious research institutions. Their advanced skills and hands-on experience make them highly sought-after professionals in the industry.

EXCELLENTTrustindex verifies that the original source of the review is Google. I recently completed my Python internship under the guidance of Mentor poongodi mam We learnt so many new things that developed my knowledge.this experience is good to learnTrustindex verifies that the original source of the review is Google. I completed my python internship guidance of mentor poongodi mam. She thought us in friendly qayTrustindex verifies that the original source of the review is Google. Poongodi mam done very well She took the class very well When we ask any doubt without getting bored she will explain,we learned so much from mam,marvelousTrustindex verifies that the original source of the review is Google. I have handled by poongodi mam.domain python intership...was goodTrustindex verifies that the original source of the review is Google. I recently completed Python internship under the guidance of poongodi mam who excelled in explaining concepts in an easily understandable wayTrustindex verifies that the original source of the review is Google. Fantastic class we were attended..we got nice experience from this class..thank you for teaching python mam...Trustindex verifies that the original source of the review is Google. -The course content was well-structured - I gained valuable insights into microcontrollers, sensors, and programming languages- The workshop was informative, interactive, and challenging, pushing me to think creatively. Ms Jimna our instructor her guidance and feedback helped me overcome obstacles and improve my skills.Trustindex verifies that the original source of the review is Google. The learning experience was really worth since more than gaining just the knowledge all of the inputs were given in a friendly and sportive manner which then made it a good place to learn something with a free mindset... 👍🏻Trustindex verifies that the original source of the review is Google. I recently completed my full stack python intership under the guidance of mentor Gowtham,who excelled in explaining concepts in an easily understand mannerTrustindex verifies that the original source of the review is Google. Gowtham-very interesting class and I learning so many things in full stack python development and I complete my internship in Pantech e learning and it is useful for my career

FAQ

How do I simulate a basic battery module in MATLAB/Simscape?

To simulate a basic battery module in MATLAB/Simscape, you can use the “Simscape Electrical” toolbox to model the battery’s electrical behavior. The basic setup involves using an equivalent circuit model (typically a Thevenin or RC model) to represent the battery and integrating it with the power source and load components.

How can I simulate a battery pack with cell aging in Simulink?

To simulate cell aging, you need to account for factors like capacity loss, increased internal resistance, and voltage decay over time. This can be modeled using a combination of empirical data and aging models. In Simulink, you can modify the battery model by reducing capacity or altering parameters to reflect the degradation process.

How do I estimate the State of Charge (SOC) of a battery in Simulink/Simscape?

SOC can be estimated using methods such as coulomb counting, Kalman filters, or unscented Kalman filters. In Simulink, the coulomb counting method integrates current over time, while Kalman filters use a dynamic model of the battery and its measurements to estimate SOC with higher accuracy and noise reduction.

How do I estimate the State of Health (SOH) of a battery in Simulink?

SOH is typically estimated by monitoring capacity fade, internal resistance, and other performance metrics. In Simulink, you can model the battery’s degradation over time and compare the current behavior to the initial conditions to estimate the health of the battery.

How can I test a Battery Management System (BMS) in Simulink?

Testing a BMS involves simulating various conditions, such as different charging/discharging rates, thermal effects, and fault scenarios (e.g., overvoltage, undervoltage, and overcurrent). In Simulink, you can model these conditions and implement control strategies to test the BMS’s response.

How can I generate code for a BMS from Simulink?

You can use Simulink’s embedded coder to generate C code from your BMS model. This code can be deployed to microcontrollers or embedded systems such as the NXPS32K for real-time operation and testing.

Start Your Tech Journey Today

Sign Up for Exclusive Resources and Courses Tailored to Your Goals!

© 2025 pantechelearning.com